“Rice lab’s battery recycling process is cleaner, cheaper

Demand for valuable metals needed in batteries is poised to grow over the coming decades in step with the growth of clean energy technologies, and the best place to source them may be by recycling spent batteries.

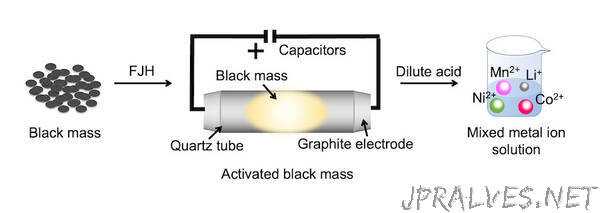

A battery recycling process developed by Rice University scientists can remove the inert layer on battery metals and lower their oxidation state, making them soluble in low-concentration acid. Using its signature Joule-heating technique to bring the combined cathode and anode waste to temperatures above 2100 degrees Kelvin in seconds, the lab of Rice chemist James Tour achieved a metal recovery yield exceeding 98% from various types of mixed battery waste.

“We developed a high-yield, low-cost method of reclaiming metals directly from ‘black mass’ ⎯ the combined cathode and anode waste the industry traditionally tries to recycle ⎯ that significantly reduces the environmental footprint of spent battery processing,” said Jinhang Chen, a Rice chemistry graduate student and co-lead author on a study published in Science Advances.

Not only does the new method significantly reduce secondary waste streams from the contaminated, acidic leaching solutions, but it also cuts the duration of the recycling process by almost 100-fold.

“It takes less than 20 minutes to dissolve the same amounts as opposed to 24 hours,” Jinhang Chen said. “Our findings have the potential to reduce the cost of battery waste recycling through decreased energy, water and acid consumption and lower carbon dioxide emissions.

“Notably, the metals’ leaching kinetics is improved from the combined effects of decomposing the passivated layer and regulating the metal valence state for the first time,” said Weiyin Chen, a former Rice chemistry graduate student and co-lead author.

The process could help supercharge the battery recycling business ⎯ a market that’s expected to grow rapidly as the batteries powering electrical vehicles and other electronics expire.

“Battery recycling is a very big deal, especially now,” said Tour, Rice’s T.T. and W.F. Chao Professor of Chemistry and a professor of materials science and nanoengineering. “Batteries in electric vehicles last about 10 years, and many of those are coming due now, because it’s been about 10 years that we’ve been using them.”

Aside from helping reduce the environmental harms of mining, recycling spent batteries is an economically sound practice as the concentration of metals like cobalt and nickel is higher in many types of lithium-ion batteries than in natural ores.

“Currently, 95% of batteries are not recycled because we don’t have the capacity to recycle them, even as waste from electronics is increasing at an annual rate of 9%” said Tour, whose lab previously developed a process for recycling battery anodes. “A lot of current battery recycling processes involve the use of very strong acids, and these tend to be messy, cumbersome processes.

“What we found is that if you ‘flash’ the black mass, then you can easily separate out the critical metals using only low-concentration hydrochloric acid. You could say the flash liberates the metals, so they dissolve easier. We’re still using acid, but much less. That’s why the economics is so much better.”

The study includes a life-cycle assessment comparing the new process to different current methods of battery recycling.

“This study has the capacity to motivate the growth of battery waste management and contribute to the mass production of electrical vehicles at a more competitive cost by lowering the cost of battery production,” Chen said.

The research was supported by the Air Force Office of Scientific Research (FA9550-22-1-0526), the U.S. Army Engineer Research and Development Center (W912HZ-21-2-0050), the Department of Energy’s Basic Energy Sciences program (DE-SC0012547) and the Welch Foundation (C-2065-20210327).”