“We live in a world where we want our electronics to be flexible, bendable and stretchable apart from being intelligent. Printed electronics technology has emerged as the main route to enable this vision. A team of researchers from Aarhus University has now published a comprehensive review of its development that will enable researchers to address problems within this field.

Next-gen electronics is envisioned to be non-rigid, component-free, flexible, bendable, and easily integrable with different objects.

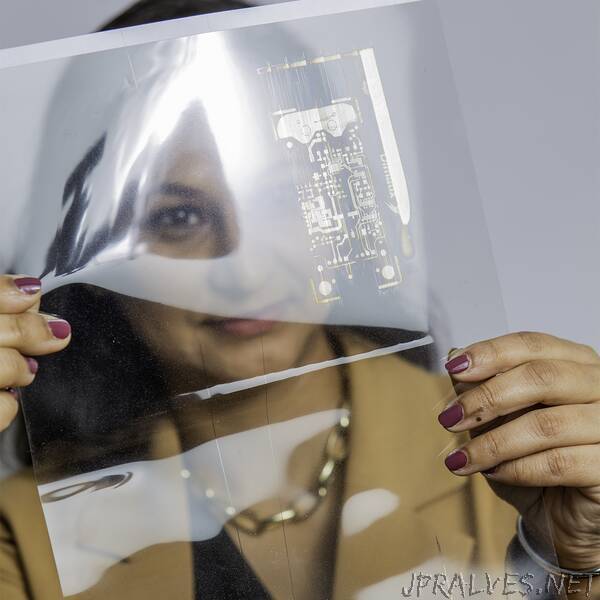

Direct-write printing techniques provide unique opportunity to enable this vision through use of nanomaterials, so-called functional inks, that can be tailored to add desired functionalities on various flexible substrates, such as textiles or plastic.

The technology, known as Printed Electronics (PE), has been known for decades, but has recently gained considerable attention due to innovation in material inks, process technology and design revolution.

To keep the research community abreast with the latest technological advancements in the area of droplet-based PE techniques for next-gen devices, researchers from Aarhus University have now published a comprehensive review of the technology in the prestigious scientific journal Advanced Materials.

“Through this paper, we have tried to fill the existing void in literature by discussing techniques, material inks, ink properties, post processing, substrates and application to provide a complete guide. PE is an industry relevant technology and the gateway to future portable electronics, where advanced printers can print complex circuits on any material,” says Assistant Professor Shweta Agarwala, an expert in PE at the Department of Electrical and Computer Engineering at Aarhus University.

PE is already being used for many different applications today. It is an attractive method to impart electrical functionality on any surface and the major advantage of PE is that it is inexpensive and readily scalable.

“PE offers a wide range of advantages over conventional lithography-based technologies. It provides much more production flexibility, it is cheaper and far simpler. More importantly, it opens up a plethora of new possibilities to print flexible electrical circuits directly onto a wide range of substrates such as plastics, papers, clothes, and quite literally any other planar and non-planar surfaces. The research area is moving forwards fast, and this publication provides an overview of how far we have progressed today,” says Hamed Abdolmaleki, a PhD student and first author of the paper.

ALSO READ: Award for research into artificial intelligence

Even though PE is being used in more and more industries, and is considered very important in the electronics of the future, the technology is still in its infancy.

For Shweta Agarwala, the sustainability aspect is very important for the future perspectives of electronics and PE technology:

“PE is the way towards biodegradable electronics, and with this technology, we can address the huge societal problems that electronics already present, and which will only get more pressing in the future. The world is not only suffering from a huge amount of plastic pollution; it is also burdened by enormous pollution from electronics in all the devices we discard rapidly. In the review article, we have also discussed the emerging field of biodegradable substrates that will have huge environmental impact,” she adds.”