“Sensitive force measurements made with submillimeter-sized device could be useful for manipulating small objects or measuring liquid surface tension.

Researchers have developed a tiny fiber optic force sensor that can measure extremely slight forces exerted by small objects. The new light-based sensor overcomes the limitations of force sensors based on micro-electro-mechanical sensors (MEMS) and could be useful for applications from medical systems to manufacturing.

“Applications for force sensing are numerous, but there is a lack of thoroughly miniature and versatile force sensors that can perform force measurements on small objects,” said research team leader Denis Donlagic from the University of Maribor in Slovenia. “Our sensor helps meet this need as one of the smallest and most versatile optical-fiber force sensors designed thus far.”

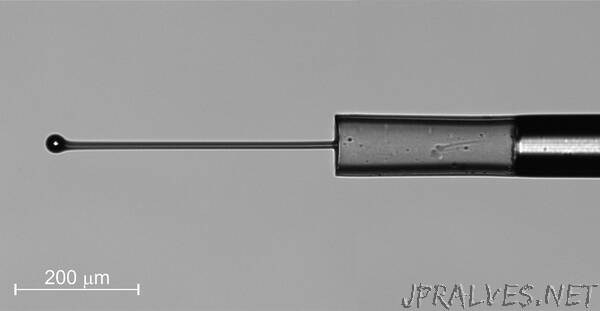

In The Optical Society (OSA) journal Optics Letters, Donlagic and Simon Pevec describe their new sensor, which is made of silica glass formed into a cylinder just 800 microns long and 100 microns in diameter — roughly the same diameter as a human hair. They demonstrate the new sensor’s ability to measure force with a resolution better than a micronewton by using it to measure the stiffness of a dandelion seed or the surface tension of a liquid.

“The high resolution force sensing and broad measuring range could be used for sensitive manipulation and machining of small objects, surface tension measurements on very small volumes of liquid, and manipulating or examining the mechanical properties of biological samples on the cellular level,” said Donlagic.

Creating an all-glass sensor

Although MEMS-based sensors can provide miniature force sensing capabilities, their applications are limited because they require application-specific protective packaging and multiple electrical connections. Without proper packaging, MEMS devices also aren’t biocompatible and can’t be immersed in water.

To develop a more versatile miniature force sensor, the researchers created an all-optical fiber optic sensor completely made of glass. The complex undertaking was made possible by a special etching process the researchers had previously developed to create complicated all-fiber microstructures. They used this micromachining process to create a sensor based on a Fabry-Perot interferometer — an optical cavity made from two parallel reflecting surfaces.

The end of the sensor’s lead-in fiber together with a thin flexible silica diaphragm were used to create the tiny interferometer. When external force is exerted onto a silica post with either a round or cylindrical force sensing probe on the end, it changes the length of the interferometer in a way that can be measured with subnanometer resolution.

The way the sensor’s structures were fabricated created an air-sealed cavity that is protected from contamination and amenable for use in biochemical environments. Not only can it be immersed in a variety of liquids, but it can also measure positive and negative forces and doesn’t need any additional packaging for most applications.

Measuring tiny forces

After evaluating and calibrating the sensor, the researchers used it to measure Young modulus – a measure of stiffness – of a human hair and common dandelion seed. They also measured surface tension of a liquid by measuring the retraction force when a miniature cylinder was removed from a liquid. The researchers were able to measure force with a resolution of about 0.6 micronewtons and a force range of about 0.6 millinewtons.

“The force sensing tip can be made substantially smaller — down to about 10 microns in diameter — and can be adapted to perform various force sensing tasks,” said Donlagic. “The miniature force sensor can also be used to create more complex sensors such as sensors that measure magnetic and electric fields or determine the surface tension or flow of a liquid.”

The researchers say that the current version of the sensor is ready for use. However, improving the overload robustness, producing probe tips with other shapes or adding miniaturized packaging could further expand potential applications. The researchers are also working to automate the processes used to fabricate the sensor to make it more practical.

Paper: S. Pevec, D. Donlagic, “A miniature all-fiber force sensor,” Opt. Lett., 45, 18, 5093-5096 (2020).

DOI: https://doi.org/10.1364/OL.401690.”