“One thing holding back e-waste recycling is the actual recycling process itself. We need cheaper, safer, cleaner, or more effective methods of separating and recovering the valuable elements from electronics before we can make the whole endeavor more attractive and profitable. Some current methods use large amounts of energy to melt components down, but chemistry could provide some tempting alternatives.

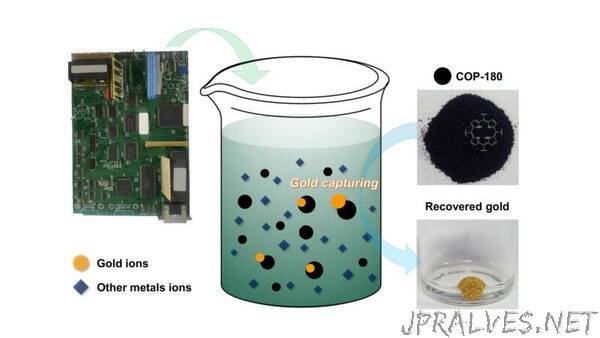

A new study led by Yeongran Hong of the Korea Advanced Institute of Science and Technology involves a chemical with an impressive affinity for gold. Subject some circuit boards to an acid treatment to release its materials and this stuff will gather up all the dissolved gold. And after it lets go of that gold, it’s ready to be used again.

The researchers’ gold-scrubber is based on an organic compound called a porphyrin. Linked together in a polymer, it possesses lots and lots of little pores that, energetically, want to host a metal atom. That’s the kind of structure chemists look for to help with recycling.

The researchers put their polymer through a number of different tests to work out which metals it worked best on and how much it could capture. It’s most effective with a small number of precious metals, most notably gold. In fact, compared to the number of pores in the polymer, they found it was capturing about 10 times as many gold atoms. For other elements like platinum, each pore only hosts one atom (responsible atomic social distancing, shall we say). But gold atoms seemed to make a party at each pore.

That behavior was verified by measurements and explained by some modeling. The researchers found that the polymer would interact with the gold atom—aided by ultraviolet light—and hand it some electrons, which happens to make it possible for more gold atoms to join in a clump. Sure enough, repeating the test with varying amounts of ultraviolet light had an impact, although capture was still quite high even without it.

Finally, the polymer was put through a pretty authentic test. The researchers took seven circuit boards from a junkyard and put them in an acid bath to leach out the metals. Then they mixed in their polymer, adjusted the solution, and kept it stirring for a couple of days. (Although other tests showed that 99 percent of gold can be scavenged in about 30 minutes.) Filtering separated out the polymer and its haul of gold. Adding acid again causes the polymer to let go of the gold, which precipitated as a solid nugget that accounted for 94 percent of the gold leached from the circuit boards.

Given the results, the economic case for this technique seems easy to make. The researchers say the polymer costs about $5 per gram to produce, and that gram can capture $64 in gold. And since the polymer can be reused, it would be considerably cheaper than that over time, adding little to the overall cost of a recycling operation.

“Although [printed circuit boards] contain more precious metals than the ores in mines,” the team writes, “80 percent of this waste still goes to landfills chiefly because of the lack of selective, high-yield, noncyanide recovery procedures.” As similar processes are found to more easily harvest other elements, all that waste is going to increasingly look like economic opportunity—and help close the loop by turning old devices into new ones instead of trash.

PNAS, 2020. DOI: 10.1073/pnas.2000606117 (About DOIs).”