“Ultrashort optical pulses are useful for a wide range of applications such as processing materials via strong light-matter interaction. In the frequency domain, a train of pulses represents an equidistant grid of frequency lines, known as an “optical frequency comb”, which is essential for timing, metrology and spectroscopy.

Though frequency combs were first demonstrated in complex mode-locked laser setups, it was demonstrated more than a decade ago that they can also be generated in microresonators with sufficiently high quality (Q) factor. This technology, known as “soliton microcomb”, has been rapidly evolving in the past years, yielding new techniques in compact forms and simplified structures, such as frequency synthesis and dual comb spectroscopy.

A key goal in the field is to build high-Q microresonators on a microphotonic chip that can be integrated into electronic devices for portable applications. To this end, modern CMOS-compatible fabrication techniques must be utilized, which have been developed for decades and used in the semiconductor industry. Silicon nitride (SiN), widely used as diffusion barriers in integrated circuits, is the most promising material to construct microresonators based on integrated waveguides. Yet, currently the Q factor of SiN microresonators is still comparatively low. Therefore, to generate soliton microcombs in SiN microresonators, complicated and power-hungry setups including optical fiber amplifiers are still needed, which makes the target – “building a soliton microcomb on a chip” – extremely challenging.

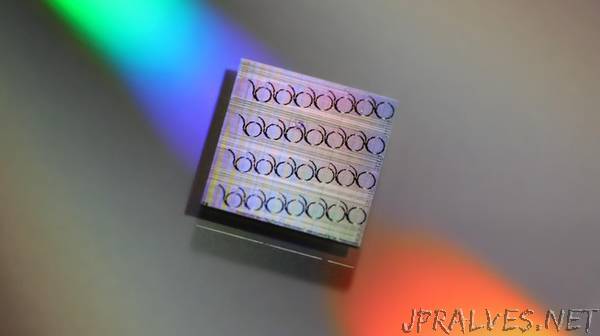

In a new paper published in Optica, the EPFL research team led by Prof. Tobias J. Kippenberg has developed a novel, CMOS-compatible fabrication process to create photonic integrated waveguides based on SiN, with light propagation loss below 1dB per meter, exceeding the state of the art by a factor of more than a hundred. Using these waveguides to build SiN integrated microresonators with Q factor exceeding 15 million (corresponding to a power enhancement of 10,000 times inside the microresonator), soliton microcombs are observed, with a record-low device input power below 10 mW. This power level, which can be achieved by a normal laser pointer, bridges the gap between nonlinear optics and silicon photonics, allowing the generation of ultrashort pulses on a silicon chip. Such devices pave the way for compact soliton microcomb chips in portable devices for metrology and spectroscopy, with much reduced cost and system complexity.

“It has been a longstanding question whether soliton microcombs can be generated on chip with a laser power below 100 mW, which has been achieved with the state-of-art integrated lasers on silicon. Now we provide our solution to this question,” said Prof. Kippenberg, the head of EPFL’s Laboratory of Photonics and Quantum Measurements (LPQM), who led the team to reach such a milestone. “It took us a long time to solve the outstanding challenge of reducing the power budget for soliton microcomb generation,” he added, “with this technology, a lot of new physics and applications are now possible to investigate”.

“To reduce the light propagation loss in the SiN waveguides, the fabrication process needs to reach a level where the control precision of waveguide geometry is at nanometer level,” said Junqiu Liu, the first author of the publication, who developed and fabricated the SiN chips. “We spent a long time to find the solution. Thanks to the Centre of MicroNanoTechnology (CMi), the cleanroom of EPFL, we are able to develop a fabrication process which enables such nanometer patterning precision of the waveguides, “he added.

With the SiN microphotonic chip, which is only 0.5 mm * 0.5 mm, the LPQM team demonstrated soliton microcomb generation with only 10 mW laser power, and a train of coherent pulses with less than 100 GHz repetition rate. “In the future, to build your own frequency comb device, all you need is a laser pointer and a SiN chip. That’s all, “according to Junqiu Liu. With a system of such a small volume and high power-efficiency, new applications using microcombs are possible to realize. Currently, the LPQM team are collaborating with their colleagues in US and Europe, to integrate this technique with mature silicon photonics technology and to build fully integrated systems, which can be employed in data centers for telecommunications.”