“Lawrence Livermore National Laboratory (LLNL) researchers have received $1 million from the Department of Energy to improve the energy efficiency of copper-based catalysts to convert carbon dioxide into methane and other valuable hydrocarbon products.

Led by LLNL’s Juergen Biener, the project will help meet the nation’s future energy needs by converting low-cost, abundant resources into commercially viable fuels.

Catalysts play a key role in these efforts. They can convert CO2, an industrial waste product, into methane, a versatile fuel that can be readily integrated into efforts to fuel vehicles and power plants. At the same time, catalysts convert excess electrical energy produced via renewable energy resources, such as solar and wind, into chemical energy, making it easy to store the energy for future use.

However, current electrochemical catalyst technologies are energy intensive and costly, and unlikely to be competitive with traditional fuel production methods.

The new work is aimed at overcoming the limitations of current approaches that use catalysts to convert CO2 into fuels.

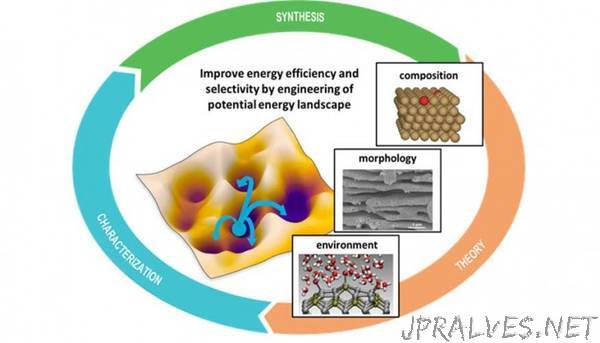

“Our goal is to optimize the performance of copper-based catalysts by improving the energy efficiency and selectivity through engineering of the potential energy landscape by tuning the catalyst composition, morphology and solution environment,” Biener said.

To achieve this goal, the team will fully integrate LLNL’s unique expertise in synthesis and characterization of nanostructured dilute alloy transition metal catalysts with atomically precise active sites, and multiscale modeling of electrochemical interfaces.

LLNL is teaming with Silicon Valley-based company Opus 12 to test CO2 reduction catalyst reactivity and selectivity.

Scientists will use LLNL’s advanced manufacturing laboratory and supercomputer facilities, and laboratories available via Opus 12, which will be used for catalyst testing under commercially relevant operating conditions.

The team also is collaborating with TOTAL American Services, a global oil and gas company, to gain valuable industry insight regarding the technology’s commercial potential and its ability to compete with traditional approaches to produce natural gas.

Team members include Brandon Wood, Sarah Baker, Monika Biener and Joel Varley from LLNL and Etosha Cave from Opus 12, with financial support from TOTAL.

In this round of funding, DOE is contributing $35 million for 24 projects to support early stage, innovative technologies and solutions in advanced manufacturing. These projects were selected under an Office of Energy Efficiency and Renewable Energy (link is external) (EERE) Advanced Manufacturing Office (link is external) funding opportunity, focused on advanced materials, advanced processes and modeling and analysis tools for materials and manufacturing.

This funding opportunity allows selected projects to perform early stage research and development of new advanced manufacturing technologies, as well as encourage R&D contributions from new partners. Successful projects will reduce technical uncertainty and develop new knowledge associated with potential breakthrough materials, processes and tools for U.S. manufacturers that could improve their competitiveness and enhance their energy efficiency.

The selected projects vary in levels of maturity and industry-readiness — from concept definition (focused on specific experimental proof or detailed analysis) to proof-of-concept (requiring physical experimental validation). As a result, proposed funding levels and project durations are tailored to the work scopes necessary to advance the technologies to the proposed readiness levels. Individual awards vary between $250,000 and $2.5 million.”