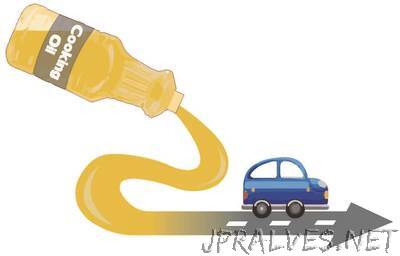

“The idea of recycling waste cooking oil into biodiesel fuel is nothing new. For years, researchers have studied the process and companies have recycled when possible. However, for many groups, cost is often the determining factor for making the effort to recycle.

The U.S. alone produces 11 billion liters – 2.9 billion gallons – of waste cooking oil a year. The costs of collecting and shipping a volume of that scale are daunting. And you still have to factor in the process to recycle that oil into a usable biofuel.

A Missouri University of Science and Technology professor believes he has the solution to cut those costs and increase the use of recycled biofuel.

“What we need to do is make the whole process on a smaller-scale so it becomes a local project for towns and cities,” says Dr. Joseph Smith, the Laufer Endowed Chair in Energy and professor of chemical and biochemical engineering at Missouri S&T. “50 percent of the cost of recycling waste cooking oil is tied up in collection and shipping logistics so let’s cut out the shipping costs and make biofuels locally.”

Smith believes that a small, modular skid-mounted facility would result in numerous smaller plants that would benefit the entire biodiesel industry by making it “greener” all-around. Regional plants would simplify collecting and processing and would boost local economies in smaller cities by creating jobs, he says.

One snag that halts many waste cooking oil recycling projects is a byproduct of the manufacturing process – glycerol. As the biodiesel industry expands, the excess of crude food-grade glycerol mixed with salt and water is relatively unused. Smith says he has a solution for that, too.

“Most companies get rid of waste crude glycerol by either burning it or using it for dust suppression instead of repurposing it,” says Smith. “Our process operates at super-critical pressures which eliminates salt production. We then concentrate and ferment the glycerol/water mixture and recycle methanol to make more biodiesel. This significantly reduces the amount of waste glycerol which makes our process more sustainable.”

The research could lead to biodiesel-propelled vehicles that are flex-fuel-powered with drop-in fueling compatibilities, says Smith. He sees this as the first step in the business-development cycle that could boost several “green” technologies. Smith’s work is funded by the National Science Foundation.

Smith earned Ph.D., master of science and bachelor of science degrees in chemical engineering from Brigham Young University in 1990, 1984 and 1983, respectively. He holds several U.S. patents, has authored or co-authored more than 40 technical papers, book chapters, and reports, and presented at more than 50 technical conferences. Smith’s research focuses on next-generation hybrid energy systems to combine small modular nuclear reactors with conventional and renewable energy sources and the design and optimization of industrial-scale coal gasification systems.”