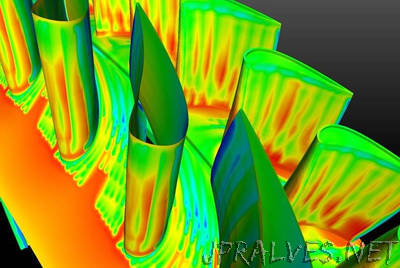

” you’ve ever seen 3D printing video, chances are it was time-lapse footage. The actual process of additive manufacturing can take hours or days, particularly when lasers are melting metal powder layer by layer into an intricate part. The simplest way to speed this up is to use higher-power lasers. But engineers can’t just turn up the laser dial to 11. That’s because the printing chamber where the metal is melted is a hothouse infused with gasses like argon and nitrogen to eliminate external influences. “If it were just a matter of integrating higher-power lasers, that would be easy,” said Waseem Faidi, who leads the additive research team for machine technology at GE Global Research. “But there’s a lot going on inside the chamber with different gas flows during the printing process that prevents you from doing that. The quality of the part being printed can be impacted.” As it happens, GE is filled with scientists who study airflows through gas, steam and wind turbines and, especially, jet engines. They try to eke out any performance advantage and efficiency gains by designing parts with special geometries and using devices such as actuators that can redirect airflows. The company calls this cross-pollination of ideas “the GE Store.” That’s why Faidi has turned for help to Aerodynamics (Aero) and Computational Fluid Dynamics (CFD) teams at GE’s labs in Niskayuna and Munich to apply their expertise. “The question with 3D metal printers is how can I control gas flows in such a way that allows us to scale up the power of the lasers in the machine beyond what is possible today?” Faidi says. “If we can figure that out, we can significantly improve the printing speed and quality of our machines today.””