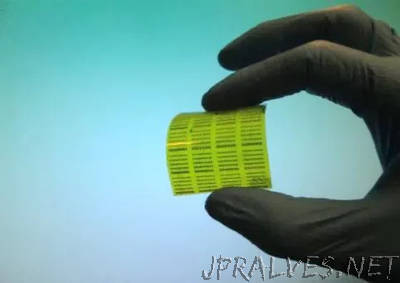

” Memory devices — as a subset of electronic functions that includes logic, sensors and displays — have undergone an exponential increase in integration and performance known as Moore’s Law. In parallel, our daily lives increasingly involve an assortment of relatively low-performance electronic functions implemented in computer chips on credit cards, in-home appliances, and even smart tags on consumer products. While memory devices are becoming progressively more flexible, their ease of fabrication and integration in low performance applications have been generally been treated as being of secondary importance. But now, thanks to the work of a group of researchers at Munich University of Applied Sciences in Germany and INRS-EMT in Canada, this is about to change. Additive manufacturing, perhaps best known because of 3-D printing, allows for a streamlined process flow — eliminating complex lithography and material removal steps at the detriment of feature size, which is in many cases not critical for memory devices in less computationally demanding uses. Inkjet printing is a common office technology that competes with laser printing. It offers the added benefit of a straightforward transfer from inkjet to roll-to-roll printing. In an article appearing this week in Applied Physics Letters, from AIP Publishing, the group presents a proof of concept, using resistive memory (ReRAM) that now paves the way for mass-producing printable electronics.”