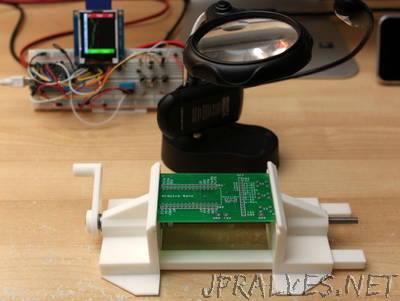

“This thing is a vise that I made to hold a PCB while soldering. It will also accomodate other light weight items. The working space between the jaws is 100mm. There are tabs on the jaws to allow the vise to be secured to a table (a little masking tape also works). It requires a 5mm diameter threaded steel rod of about 200mm in length with two or three washers, two normal nuts, and a locking nut to match. Print the handle, left and right sides, and two backbones. I printed with a layer of .36 and a fill of .25. Assemble gluing the backbones into the left (stationary) side. Locking nut in handle. Two washers between handle and left jaw. One washer (small one) and two nuts on other side of left jaw from handle with second nut locking the pair in place on the threaded rod. Final nut on outside of right (moving) jaw in recess built for it. The nuts that fit into recesses should stay put based on friction but if not use some epoxy! This is version two of what was originally uploaded. There is now a recess in the left handle for the two locking bolts. This allows the vise to close completely. There is also a second handle now included. This handle has a ball and joint feature that should allow the grip to rotate as it is turned. This does require some degree of printer precision. I would recommend printing it with a layer height of .3 or less. You may have to use some amount of force, and a pair of pliers or visegrips, to break loose any adhesion. I print everything in PLA and was concerned that melting might be an issue but in practice, have so far (but without a lot of work yet), not found this to be the case. If you have heated up the PCB enough to cause an issue with the PLA you are probably getting it too hot. If this is an issue for you I would recommend printing in ABS. An alternative might be to shield the jaws with some foil to disperse heat.”