“Reflow ovens are an important part of the development of PCB for electronic products when using surface mount components. They provide a route through which PCBs can be quickly populated with SMD components, however, for accurate results, the heat across the oven needs to be controlled and timed correctly. To achieve this, manufacturers use a kind of controller, like “Tiny Reflow Controller”, and with several DIY reflow ovens being used by makers around the world, we thought it would be a good fit for today’s tutorial to focus on the development of DIY Reflow Oven Controller.

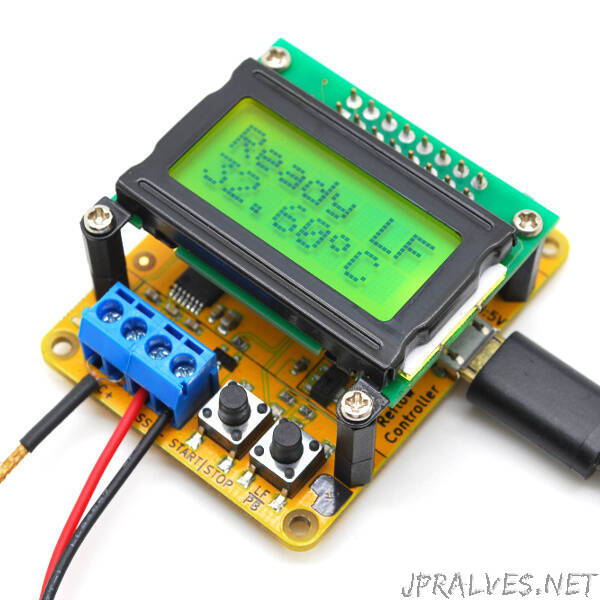

As mentioned above, reflow oven controllers are quite important in ensuring just the right amount of heat is applied in the soldering process for SMD components and this importance has led to the development of quite a number of different Reflow oven controller projects, which someone can find on the internet. However, for today’s tutorial, we will look at the first version of Rocket Stream’s tiny Reflow Oven Controller v1 which is probably the most well tested DIY reflow oven controller on the internet, as it is the one being used by Rocket Stream themselves for the manufacturing of their boards.The Rocket Stream’s Reflow Oven Controller v1 is powered by the ATtiny1634R and uses the latest thermocouple sensor interface IC MAX31856 from Maxim. It is one of the cheapest designs on the internet as Rocket Stream was able to reduce the overall cost of the design by not using a development board like the Arduino and using as many SMD parts as possible in place of through-hole components, to reduce the time that goes in and the work involved leaving only the terminal block and the LCD connector as the only through-hole components.The ATtiny1634R is one of the new ATtinys we discussed in the last article. It is a High Performance, Low Power AVR® 8-bit Microcontroller with Advanced RISC Architecture, 16K Bytes of In-System, Self-Programmable Flash Program Memory and 256 Bytes of In-System Programmable EEPROM with support for up to 100,000 Write/Erase Cycles. It comes In-System Programmable via SPI Port and can be programmed using the Arduino IDE.Other components involved include an external Solid State Relay (SSR) which should be rated according to the current draw of your oven (heater) and a K type thermocouple which provides temperature feedback to the controller and an LCD on which information/status of the system is displayed.At the end of this project, you know the workings behind the Tiny Reflow Controller and you will have built up the courage required to attempt building one by yourself.”